Eliminate the operator / equipment waiting for a waste of time, Greatly improved work efficiency!

NS-AT6101-3 PRODUCT FEATURES

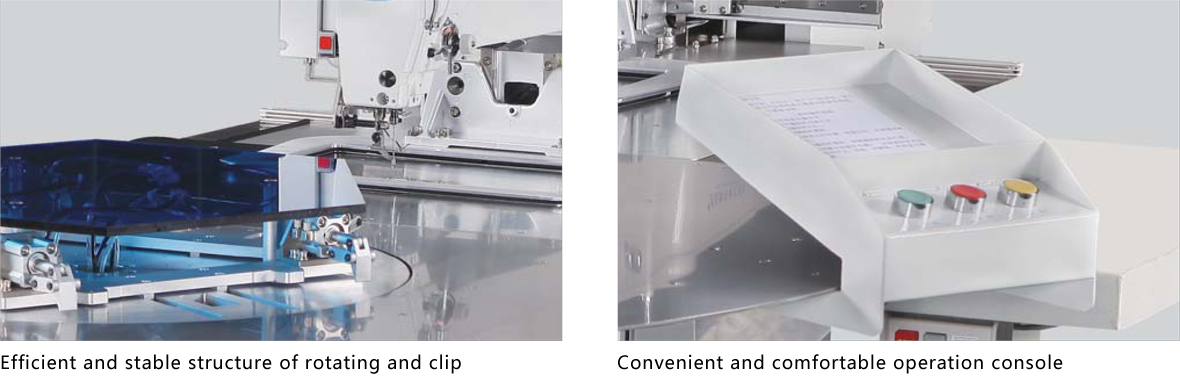

1. Three rotary working table can achieve the same fabric on the multi-level combination of patterns, the same equipment continuous sewing, improve equipment Jia moving rate, which greatly improve production efficiency.

2. Sewing and clamping synchronization, eliminating the operator / equipment waiting for the time to waste, improve work efficiency;

3. Automatic alignment, automatic sensor to read the sewing pattern;

4. Can automatically switch a variety of patterns automatically;

5. Applicable to multi-species small batch multi-layer combination template;

6. 3 times the traditional process, can save 1 person.

Return on investment: in accordance with the monthly wage of 4,000 RMB per year, the annual savings of 4000 x 12 = 48,000 RMB

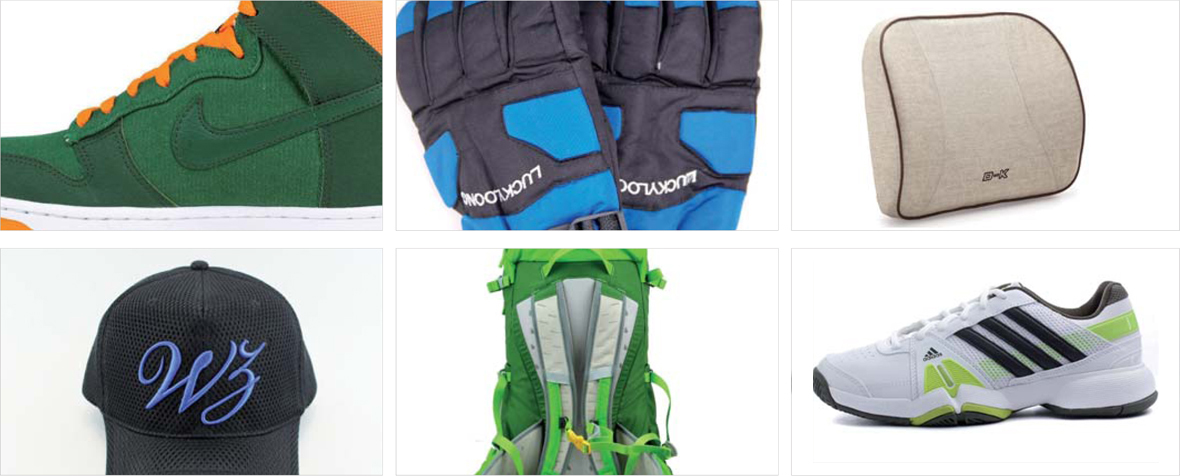

NS-AT6101-3 Application Example

SPECIFICATIONS

Stitch

Single-needle flat seam

Max. sewing speed

2800 rpm

Sewing area (X × Y)

Max. 400×300mm

Feeding device

Intermittent feed (pulsed motor drive)

Stitch length

0.05-12.7mm

Max. number of stitches

20000 needle / 1 pattern

Press the foot drive mode

pneumatic

Height of presser foot

Max. 30mm

Two-step presser foot

One-piece presser foot

Intermittent pressure rise

22 mm

Intermittent pressure on the trip

0或(or)2 - 10 mm(Factory Setting:3mm)

Hooks

Twice the shuttle (standard shuttle is optional)

Sweep line device

Standard equipment

Tangent device

Standard equipment

Gripper

Variable electronic gripper

Motor

AC servo motor 750W

Power supply

Single phase100~120V、200~240V、Three phase 200~240V、380~415V、350V

Air pressure

0.5Mpa、1.8L/min

The above types are only for reference, and you can consult local distributors for details.

Specifications are subject to change for improvement without further notice. Please carefully read the operating manual before use for safety.

Specifications are subject to change for improvement without further notice. Please carefully read the operating manual before use for safety.